Kiln Emergency Demo

EMERGENCY JOB | COATING AND BRICK DEMO // ROBOTIC DEMOLITION

A customer had an emergency job needing to replace brick on their cement kiln due a hot spot at the 76-foot mark. Our team was on site to start the demo 24 hrs after the customer’s call. Our team arrived with two demolition robots and two bobcats ready to go.

PROJECT DETAILS

Key Project Elements

TECHNICAL ANALYSIS

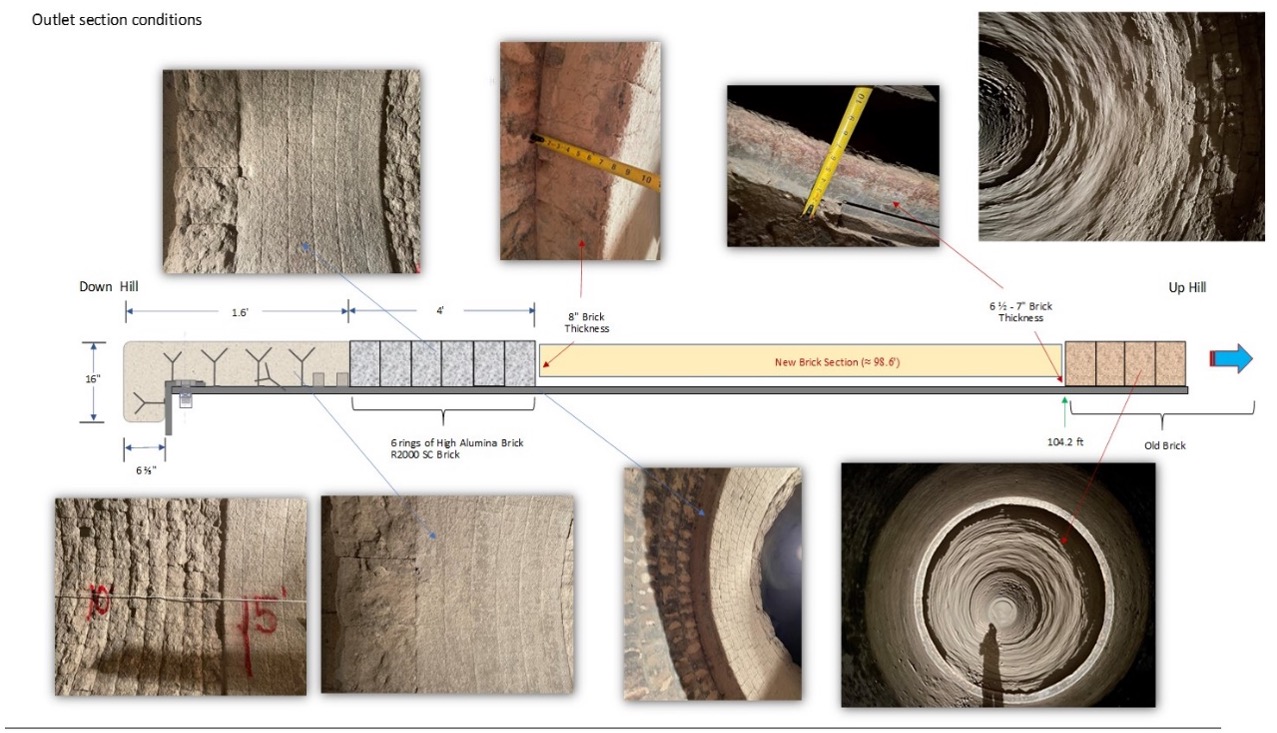

Our technical team began analysis of the coating upon immediate arrival on-site and collecting data throughout the entire demo project. The coating had an even shape with 8.3" average of thickness. In the end of the kiln (uphill), there were two coating rings. However, we couldn't measure as they collapsed one of the kiln turns during demolition. We measured the brick and identified capping between 21 ft and 60 ft. In this section, the brick was losing 1-3" of thickness. No section was twisted/spiraled. To identify the cause of the loss of thickness, we'd need to perform as detailed stuck and conditions of the process and compare to the last ovality study looking for possible mechanical stress.

DETAILED DATA, CHARTING + REPORTING

Our technical team collected a significant amount. of data to chart and build a thorough report of the kiln, which could be used by the customer long-term to help with future efficiency, performance and repairs. We charted brick thickness so we could analyze the best lifetime of the brick.

ROBOTIC DEMOLITION

We demoed coating from 1-63 ft then turned the kiln to feed the coating to the clinker cooler. We then demoed brick from 5.6 ft to 104.2 ft (98.6 ft) and mucked the brick out in 3 steps (1) demo from 45 ft to 90 ft, (2) demo 5.6 ft to 45 ft, then (3) demo 90 ft to 104.2 ft.

At ELITE we handle every aspect of refractory installation, maintenance and repairs with the highest quality of craftsmanship, experience, materials and detail. We developed our skill sets from being on the job for several decades, working for many of the most well-known manufacturers in the world.

We know that minimizing outages and reducing downtime is of the upmost importance. With one of the most experienced and knowledgeable teams in the industry, we’re built to support large outages and repairs.

That’s what makes us ELITE.

We are a proud portfolio company of the American Industrial Services Group (AIS).

Sign Up to Receive Monthly Emails

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact