Clients

Cement + Lime Industry

Team

Technical Team + Workshop Management Team

Services

Pre-cast job at the Refractory Shop

Category

Critical Refractory Inspections + Repair

Pre-cast jobs in the refractory shop. Main components of the projects are demo, metal work and refractory installation. We pick up parts from the customer site, refractory demo, remove metal anchors, grinding sleeves and fix at our shop. We install insulating pipe around this burner pipe and damper. Weld the metallic anchors and build forms to pour to make the refractory cast. Then we cure the pipe, build a technical report and deliver to the customer when it is fully cured and ready for installation.

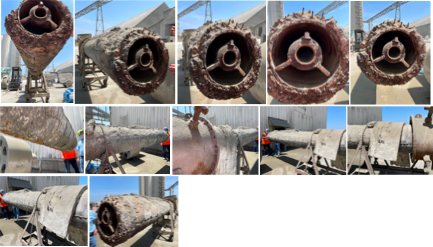

Pickup parts from Customer site

Refractory demo

Metal anchors removed & fix grinding sleeves

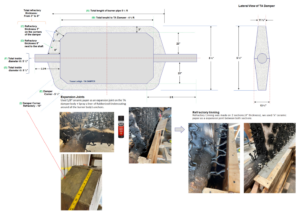

Install insulate material around the burner pipe & damper

Welding metallic anchors

Build forms and pour refractory castable

Curing process

Build technical report

Delivery to the customer

24/7 Tech. support across US

Our technical & workshop management team work together on all the workshop projects to reach the best quality and design, looking for the best performance of the materials used.

Pickup and delivery services

Mechanical and welding capacity

Knowledge on the fabrication of forms and shapes

Ability to mix and pour Refractory materialTechnical supervision on the shop all the time

Capacity to cure concrete and tracking the temperature of the process

Technical report as needed

More than 15,00 ft² workshop size allow us to work and build larges pieces or equipment

Pick up next day the customer contacts us

Knowledge analyzes technical information from the customer

Years of experience on both Welding and Refractory

Data of the Curing process

Cement & Lime - Kiln Alkali Quench Duct

At ELITE we handle every aspect of refractory installation, maintenance and repairs with the highest quality of craftsmanship, experience, materials and detail. We developed our skill sets from being on the job for several decades, working for many of the most well-known manufacturers in the world.

We know that minimizing outages and reducing downtime is of the upmost importance. With one of the most experienced and knowledgeable teams in the industry, we’re built to support large outages and repairs.

That’s what makes us ELITE.

We are a proud portfolio company of the American Industrial Services Group (AIS).

Sign Up to Receive Monthly Emails

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact