Client

Cement + Lime Industry

Team

Technical Team + Refractory Sepecialists

Services

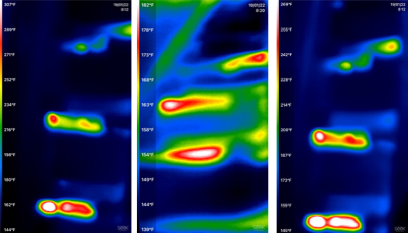

Thermal Inspections + Clinker Cooler Roof Hot

Category

Critical Refractory Inspections + Repair

We performed a Thermal Inspection on a Kiln Clinker Cooler that had a hot roof. We identified refractory hot spots and compared the thermal profile with the job during the outage. After analyzing the anchor system and refractory installation we can offer alternative custom solutions to resolve the heat disposition issues.

Thermal Inspections

Temperatures profile

Technical report

Experience on anchor systems

Design refractory installation

Refractory installation

24/7 Tech. support across US

Refractory specialist team w/technical equipment & knowledge of refractory & cement industry available to helping the new generations of production members at the plants.

Visiting plant same day customer contacts us.

Knowledge to collect & evaluate data of the situation.

Years of experience in both industries (cement & refractory) allow us to propose alternatives to control & improve the situation.

Building & submitting technical report for the customer.

Once the problem was identified a solution needs to appear quickly and right. The worldwide refractory training of our team permits us to suggest alternatives. Such as how important it is to know that the use of mortar between bricks will help to seal the brick job; or how important is consider place a beam across the roof from outside helps to reinforce the metal structure without affect the heat dissipation.

Cement & Lime - Refractory Services + Fabrication

We know that planning is the key to any project and job. Good planning begins with the collection of information and data in the field. No matter what temperature the problem rises to or which equipment we need to analyze, we will be there by your side to give you all the technical support that is required.

At ELITE we handle every aspect of refractory installation, maintenance and repairs with the highest quality of craftsmanship, experience, materials and detail. We developed our skill sets from being on the job for several decades, working for many of the most well-known manufacturers in the world.

We know that minimizing outages and reducing downtime is of the upmost importance. With one of the most experienced and knowledgeable teams in the industry, we’re built to support large outages and repairs.

That’s what makes us ELITE.

We are a proud portfolio company of the American Industrial Services Group (AIS).

Sign Up to Receive Monthly Emails

By submitting this form, you are consenting to receive marketing emails from: . You can revoke your consent to receive emails at any time by using the SafeUnsubscribe® link, found at the bottom of every email. Emails are serviced by Constant Contact